Introduction

HBI is the preferred DRI product for the merchant metallics market because it is much denser than DRI, which reduces the reoxidation rate and minimizes yield losses from breakage. This enables HBI to be stored and transported without special precautions under the International Maritime Organization (IMO) code for shipping solid bulk cargoes. It can be used in the EAF, BF, and BOF. HBI is made by compressing DRI discharged from the MIDREX® Shaft Furnace at ≥ 650° C into pillow-shaped briquettes with a typical size of 30 x 50 x 110 mm and a density ≥ 5 g/cm3. No binder is used to make HBI.

Shipping and Logistic

HBI is produced from DRI, which is compacted at a temperature above 650° C to form briquettes between around 90 mm to 130 mm long, 80 mm to 100mm wide and 20 mm to 50 mm thick. HBI is a much safer form of DRI due to the fact that it is very resistant to overheating in case it gets wet. However, during the carriage, it can still make small amounts of hydrogen gas. Inverting is not required according to the IMSBC Code, but sufficient surface ventilation is needed.

The following aspects should be considered during transportation of sponge iron:

a) Material should be loaded dry, and it should be below a temperature of 65°C. Loading during rain should be avoided. If loading is done in an open area, direct contact with water should be avoided at all costs.

b) Sponge iron (DRI), prior to shipping in commercial vessels, should be stored in small heaps of approximately 50-100 t on a dry concrete surface for 3 to 4 days in order to undergo air passivation. Thereafter, smaller heaps are to be accumulated into larger heaps of approx. 1000-2000 t on the ground for at least 24 h prior to loading for temperature monitoring (at least once every 4 h) to prevent any eventual re-oxidation. If during this period, the temperature rises beyond 65°C, the material should not be loaded into the

vessel.

c) Sponge iron, if transported by sea, should be loaded in holds which are water-tight, clean and dry. The vessels should have deck ventilators to vent out any small quantity of hydrogen generated. The vessel should have nitrogen purging devices and sampling probe installed on each cargo hold to facilitate purging and measurement of oxygen and hydrogen concentration during purging as well as during voyage. Thermocouples with extended wiring should be installed in each cargo hold to facilitate continuous temperature measurement and an alarm in case of material re-oxidation and overheating, due to accidental external causes during the voyage.

d) When sponge iron is transported by trucks, it is necessary to protect the material from coming into contact with water by using tarpaulin covers, which should not fly off during the journey.

e) When sponge iron is transported by rail, closed wagons should be used.

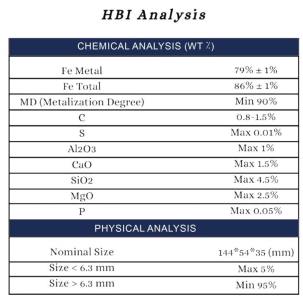

Specification

HBI OPERATIONS IN 2025

Reviews

There are no reviews yet.